lifterbar

Shargh Sepahan has more than 30 years of experience in designing and manufacturing ball mill liners and other equipment used in mines and material processing industries.

product introduction:

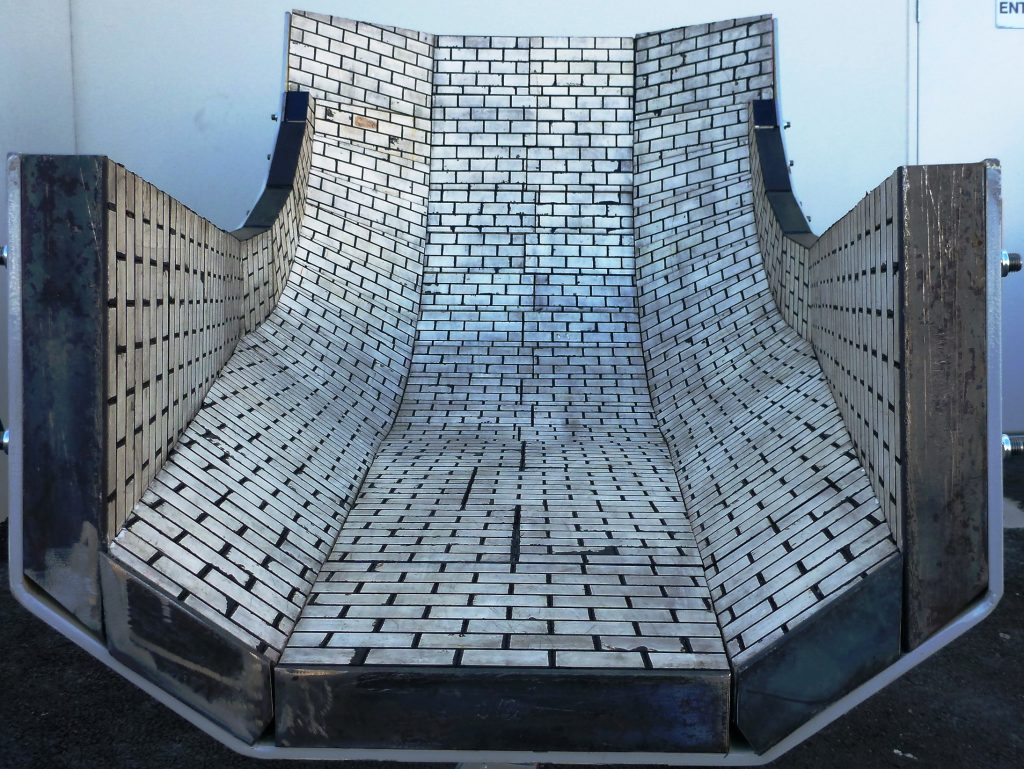

Steel composite lifterbars are still the norm in most primary and secondary milling applications. However, shargh Sepahan has produced a type of rubber and ceramic rubber lifterbars that are similar to impact lifters used in conveyors. Moving and controlling rubber forklifts is easier and their installation is faster, and by reducing the overall weight of forklifts, noise pollution and also the overall impact on rotating components are reduced.

Consistent and predictable wear rates are an advantage with rubber and ceramic rubber lifterbars, allowing sites to schedule better inspection and maintenance schedules and manage downtime more efficiently.

Shargh Sepahan offers a wide range of lifterbars and rubber and ceramic rubber plates for ball and rod mills. They come with aluminum and steel rails, with different angles to suit the grinding or washing application.