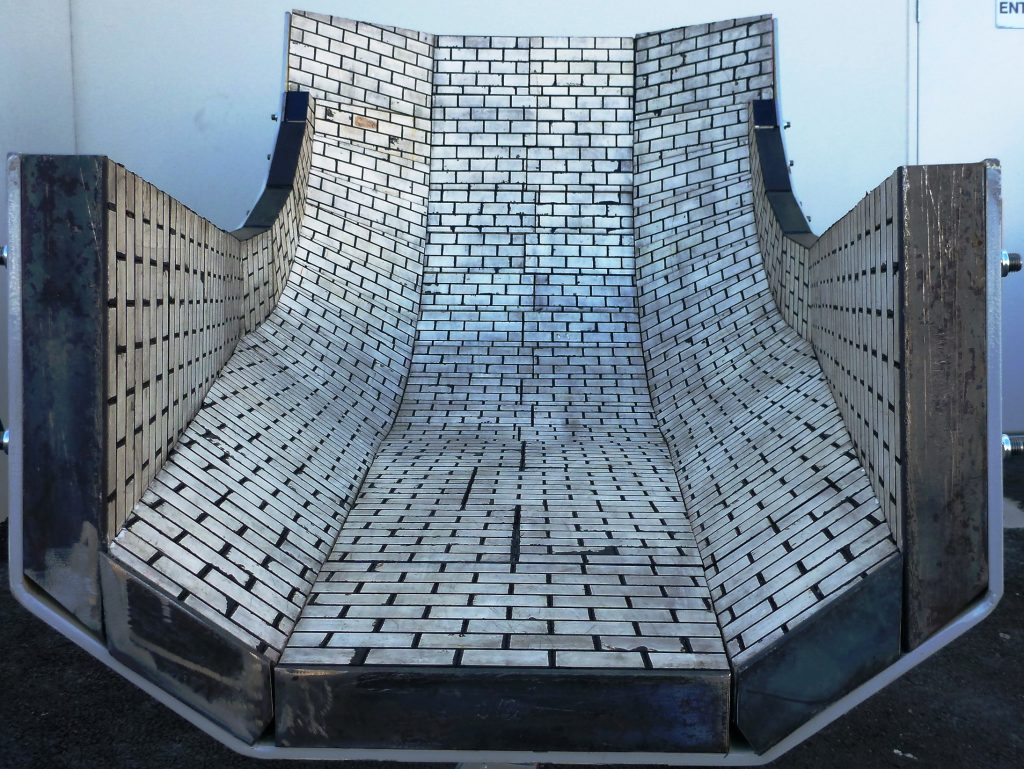

Pump liner

Rubber liners are widely used in mining applications such as slurry pumps to protect against ore wear and are critical to maximizing operational uptime.

product introduction:

Shargh Sepahan liners can extend the life of slurry pump liners by 50% or more and in some cases have been shown to double the life of the slurry pump, while increasing the efficiency of mining operators.

Fluid-exposed components of the pump are coated with a rubber coating, a distinction must be made between soft rubber coating (multi-layer coating, mainly as wear protection) and hard rubber coating (single-layer coating, mainly as corrosion protection).

Three types of elastomers are widely used in lined slurry pumps, which are used depending on the solid particle size, shape and hardness, and corrosion properties of the fluid, and include natural rubber, polyurethane and synthetic elastomers.

Natural rubber:

The use of natural rubber in liner pumps renders the wear resistance of shell liners up to 1.2 inches and other solid particles up to 1.4 inches for impeller liners. When natural rubber is used, the turbine rotational speed should be less than 5,400 ft/min to avoid liner failure due to increased temperature at the outer edge of the turbine. The use of this elastometer is inappropriate for oil, solvents and strong acids, and there is a possibility of damage when pumping larger solid particles or materials impure to them, and it is not no longer appropriate to use them for temperatures above 110 degrees Celsius.

Polyurethane :

Synthetic elastomers: